NEWS RELEASE March 2020

Holistic Non-Woven Filtration Media Program

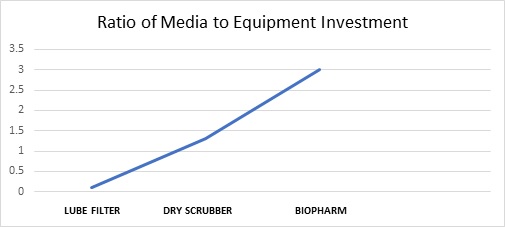

The challenge for non-woven filter media suppliers is that their place in the supply chain is remote to the end user. They cannot hear the voice of the customer. The media can be a minor investment such as in a high pressure lube filter. But in the case of fabric filter media for dry scrubbers it can exceed the equipment investment. New applications such as replacement of resins in biopharma chromatography could result in non-wovens investment which is considerably greater than the vessel which contains it. In fact with single use systems and a plastic rather than stainless vessel the media becomes the main investment.

The non-wovens media companies have both the size and attractive ROI potential to not only seek the voice of the customer but create a solution for them which meets the ever changing needs.

The McIlvaine holistic program for non-woven media suppliers includes

- Forecasts of the opportunities for each product in each industry in each country

- Assessment of competition Non-woven Filter Media Supplier Analysis

- Assistance in developing the “true cost” (cost of ownership) through cooperation with industry sources including International Filtration News which is publishing a true cost article in every issue.

- Access to specific databases with vital filter and end user analyses and contacts. Gas Turbine Inlet Filter Update

- Routes to validating true cost and convincing customers including coordination at conferences and expositions FILTXPO Shows How Filter Media Has Important Uses Beyond Particle Capture

There is a large potential for higher performance particulate filters based on the ability for inexpensive sensors to continuously monitor contaminants such as PM 2.5. In fact some office buildings in China have continuous displays.

The need for gas phase removal is growing as well. Lydall, for example, has developed laminates with absorptive layers. So the office building of the future can be displaying levels of particulate, formaldehyde and other air borne contaminants.

The coronavirus may turn out to be periodic as is swine flu and require who new permanent filtration concepts.

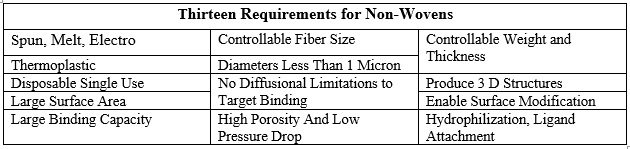

There is a big potential in the booming biopharmaceutical industry. Cost effective single use filters need to be developed. There is a big potential for non-wovens to replace resins in chromatography. Ruben Carbonell, Ph.D., chief technology officer, NIIMBL points toward large-scale biological product capture at a low cost with nonwovens. Requirements for such applications include:

With the rapid growth in gene therapy, the need for single use filters and the expansion of product scope this market could rise to several hundred million dollars per year for non-wovens suppliers.

There is even a bigger market potential in the Opportunistic Biomass - CCS Program is the Route chosen by the UK and Japan

This compromise climate change program will rely on solid fuel boilers converted to biomass firing with CO2 sequestration. This cycle removes CO2 from the atmosphere and is therefore the greenest power option. Particulate and acid gases can be removed in a dry-scrubber fabric filter. A downstream scrubber captures the CO2. The market for non-woven fabrics is potentially over $5 billion per year. It rests in part on what McIlvaine calls bag cleaning in the FIFO vs traditional LIFO mode. When both particulate and acid gases are removed in the filter the first-in lime needs to be removed when it is reacted. Media suppliers have to work with equipment companies to improve the cleaning process without impacting filter life or performance.

There is a $ billion market in catalytic filter media. FLSmidth has a fiberglass media with embedded catalyst. The result is one unit for NOx and particulate control instead of two. A high temperature ceramic candle which is offered by the partnership of Haldor Topsoe and FLSmidth can provide heat recovery along with acid gas, NOx and particulate removal.

McIlvaine Company is involved with the complete range of flow and treat products and systems for industrial, commercial, residential and mobile applications. It is therefore in a unique position to assist non-woven media suppliers

For more information on the Holistic Non-Woven Filtration Media Supplier Initiative contact

Bob McIlvaine

President

McIlvaine Company

Email This email address is being protected from spambots. You need JavaScript enabled to view it.

Phone 847 784 0013