NEWS RELEASE April 2019

Gas Turbines are a Most Profitable Market for CFT Suppliers

Suppliers of combust, flow, and treat products and services will benefit from a growing world market for gas turbine generated power. There are many opportunities which fall in the Most Profitable Market category.

- The market is growing at a rate above GDP

- There are continuing needs for improvement of CFT products

- Purchasers are oriented to purchasing products with the lowest total cost of ownership

- Access to purchasers is enhanced by the following factors

- Purchasers are mostly large companies buying components for multiple plants

- Purchasers are home based in markets well served by international CFT suppliers

- Suppliers have the opportunity to reach these customers in a manner to validate the lowest total cost of ownership of their products (LTCOV)

All of these factors create an opportunity to generate substantial sales with high profit margins. This opportunity is quantified for each CFT product in the McIlvaine CFT Most Profitable Market Program Click Here.

The inventory of existing gas turbine plants is growing at 4 percent per year and in the next few years, the base will grow to two million MWs. There are 30,000 individual units which routinely require service, replacement or repair of CFT components. The rapid cycling occurring because gas turbines provide backup power for wind and solar has resulted in serious problems. One of them is Flow Accelerated Corrosion (FAC). Suppliers of valves, pumps, and other CFT components have the opportunity to provide upgraded products to deal specifically with this condition.

Because higher performance turbines are being purchased there is a need to remove the very small particles in the turbine intake air. High efficiency glass media is relatively fragile and more expensive than the typical polymer based media commonly used. There is a big opportunity to combine efficiency and longer life to generate high margins.

Fleets of turbines are being operated remotely. Some of the operators are large power companies and others are third party service companies. Those CFT suppliers whose products can be remotely managed to provide lower total cost of ownership can boost margins. This opportunity expands to the extent that the CFT product supplier can also supply local process management programs with edge computing. This optimizes the product operation and reduces the task for the cloud based plant process management system.

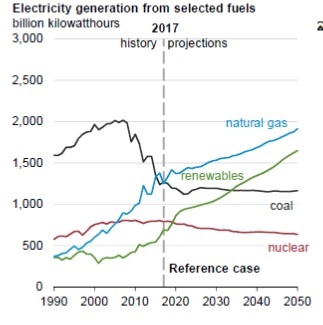

The U.S. will continue to be the largest market. This increases the profit opportunity for those CFT suppliers with a strong U.S. presence. Unlike coal fired generation, the U.S. gas turbine market will remain the world’s largest in the near future. The U.S. is replacing coal with natural gas whereas Europe is moving more aggressively toward wind and solar and Asia is continuing to rely on coal. Natural gas power generation in the U.S. already exceeds coal fired power and will grow at an average of 1.5 percent per year over the next 30 years.

U.S. Energy Production - quadrillion BTU

The CFT market is boosted by the conversions of simple cycle plants to combined cycle. Many plants which originally were peaking are now being converted to combined cycle operation and are being used at least for intermittent power to offset fluctuations in wind and solar. CFT companies have attractive markets in raw water intake, ultrapure water, and wastewater treatment. Plants in areas with tough wastewater discharge limits or water scarcity are opting for zero liquid discharge. This substantially increases the CFT investment. ZLD technology is developing rapidly. This provides the opportunity to offer products with much lower total cost of ownership.

The use of IIoT and Remote O&M will accelerate faster than in other CFT markets. The largest coal fired boiler is four times larger than the largest gas turbine. Owners are challenged with operating multiple units. Furthermore gas turbines are complex enough that OEM guidance is welcomed. MHPS, GE, and other turbine suppliers have remote monitoring centers. These centers are primarily focused on turbine issues but are expanding to cover the balance of the plant. Third party operators such as NAES are contracting to operate a number of plants. The more plants which are remotely monitored the more cost effective the results. GE cites its experience with many thousands of turbines as a major resource.

Many plants have cloud based process management systems. CFT suppliers have the opportunity to supply packages with edge based software and analytics which is tied into the process management system.

There is the opportunity for CFT suppliers to provide extensive O&M services. Air filters, catalyst, treatment chemicals, valves, pumps, measurement devices and other CFT products and services can be sold in tandem with remote monitoring to provide a total solutions approach.

There will be fewer but larger customers. Consolidation is taking place in many ways. The large operators continue to expand. Third parties are expanding their activities with the smaller operators. This provides CFT suppliers with the opportunity for direct sales contact.

The gas turbine markets as well as detailed project and plant information is continually updated in 59EI Gas Turbine and Reciprocating Engine Supplier Program.

For more details on the program McIlvaine CFT Most Profitable Market Program Click Here

The potential for automation and remote monitoring is analyzed in N031 Industrial IoT and Remote O&M.