High Performance Valve Decisive Classification Program

High Performance Valves: Markets and Selection Process

High performance (HP) valves tend to be purchased and sold using the same process as general purpose valves. Price and delivery are prioritized. Evaluation of the lowest total cost of ownership (LTCO) is not elevated to the highest priority. This failure permeates the industry even to the point that bonuses are paid on performance in the past year rather than the past 10 years. The company that buys the lowest priced HP valves does better this year but over time it will be a costly choice. The company that sells the lowest priced HP valves can book profits in the current year but subsequent expenses and loss of reputation will affect future profits.

There are several ways this condition could be corrected. The first step is to identify the high-performance valves which need to be evaluated separately. There are three main criteria:

- Severe Service

- Critical Service

- Unique Service

Severe Service: Corrosion, pressure, temperature, process operating fluctuations are all conditions that qualify an application as severe service.

Critical Service: Safety, product purity, continuous operation, and product toxicity are criteria of critical service.

Unique Service: The distinction is often made between an engineered valve versus an off the shelf or standard valve. In any case, the decision making for unique service valves needs to be made with prioritization of the LTCO.

McIlvaine Company is facilitating this identification of high performance needs by revising its market report on valves to segment the high performance and general purpose opportunities. For each industry high performance needs are further segmented by use e.g. air or water intakes, cooling, stack gas or wastewater treatment, and process. Process, in turn, is segmented by function e.g. evaporation, reaction, mixing, size separation, etc.

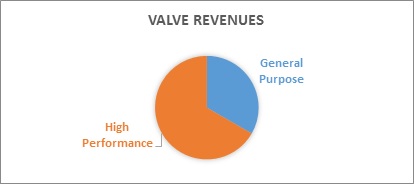

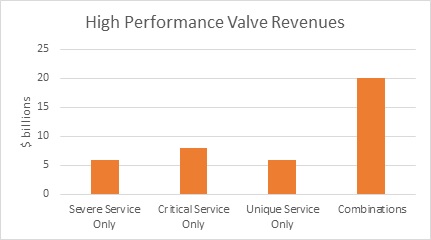

Industrial valve sales (including municipal drinking water and wastewater) will be $60 billion in 2017. Two thirds of the total will be for high performance valves.

Fifty percent of the high performance market involves valves which must meet some combination of severe, unique or critical service.

The second step subsequent to identification is to make the LTCO evaluation process less costly and more accurate. It is easy to select the lowest price or most widely used product. There is no easy way to evaluate the LTCO for each option. Purchasers often hire consultants to help them evaluate the LTCO. The problem is that with the world’s information doubling every few years, it becomes increasingly difficult to take advantage of the knowledge at reasonable cost.

To make the analysis easier for end users Mcilvaine is providing them with free Decision Guides. Guides already available or under preparation are

Valves for coal fired power plants

- Boiler feedwater

- FGD wastewater

- Pulse jet filter dust collector valves

Valves for gas turbine combined cycle power plants

- HRSG feedwater

- Pulse jet inlet filter valves

Valves for specific processes

- Molecular Sieve Switching Valves

- Choke Valves

- Power plant high temperature ball valves

- Oil and gas gate valves for service in excess of 5000 psi

The LTCO of ownership has to include the extent to which each application is subject to severe, critical, or unique service. Boiler feedwater valves for coal fired power plants encounter severe service due to high temperatures and pressures. The service is critical due to continuous operation requirements and the impact on electricity generation.

FGD wastewater valves encounter severe corrosion and erosion potential. Pulse jet filter valves are classified as high performance because of the unique service. These valves which achieve pulsing of compressed air to clean filters can be custom designed to improve performance and reduce compressed air requirements. Pentair supplies special valves and headers custom designed for each application. This approach is applied to gas turbine inlet filters as well as coal fired boiler dust collectors.

Two of the most challenging applications for valves in the oil and gas industry are molecular sieve switching and control of flow in oil and gas drilling. When switching from one dehydration sieve unit to another zeolite particles are entrapped in the gas stream and create valve problems. The choke valves used for control in drilling are subjected to sand and other abrasive particles. In addition the temperatures and pressures can be high.

The initiative to identify high performance valve applications and provide an easy way for purchasers to determine the lowest total cost of ownership option will be helpful to all operators but will be especially useful for operators in developing countries.

Choke Valves vs. Control Valves - Interview with David Johnson

David Johnson, product manager – surface chokes and subsea products for Kent Introl submitted brochures and also an analysis of choke valves which was just published last month. We will post it in our Industrial Valves: intelligence system. The data makes distinctions between choke and control valves and we wanted clarification so we asked David the following question:

Bob: What is the difference between choke and control valves?

David: The question regarding what is the difference between a choke valve and a control valve is asked often. Everyone seems to have a different understanding on what a choke is. Some people state that a choke only controls fluid out of the well and all the other applications (e.g. Water Injection/Gas Injection/Gas Lift /MEG Injection) are control valve applications.

For our range of chokes, a choke is generally upstream of the separator either attached to the Christmas tree or the adjacent pipework. API 6A 20th Edition states: -

“10.9 Chokes

10.9.1 General

Positive and adjustable chokes are chokes that include restrictions or orifices to control the flow rate of fluids.

Chokes are not intended to be used as shutoff valves.”

(A choke does one of two things, or a combination of both. It controls pressure and flow.)

Bob: There seems to be contradictions in the definitions offered by various suppliers.

David: I have noticed that in your material that at least one vendor states that Blow Down/Vent Valves/ Level Controllers/Overboard dump are also choke applications. Koso Kent Introl would consider that all these applications are actually control valve applications and we have a range of control valves for these applications. A company with a very limited range of control valves, may offer the choke to bridge the limited product gap.

Bob: What features set the control valve apart from the choke valve?

David: Even though on some applications the trim technologies in our control valve range might be similar to what we would use in a choke, in most instances the trim technology and materials of construction would be different. You can stand one of our control valves next to a similar size and rated choke valve and to the untrained eye you might think that they were the same. However, there are a number of subtle differences that enhance the design of the choke to endure the more onerous process conditions on choke applications.

Multi discipline knowledge allows judgement on both severe service and critical application

The success or failure of a valve rests not only on the valve merits but on how it is applied. Subsea pipeline valve needs are different from subsea Christmas tree needs. Both are certainly different from the needs at the surface or on shore. The best valve choice requires detailed knowledge of the unit operations. When it comes to subsea valves, there is an organization dedicated to providing the application insights.

The Valve Institute was formed by oil and gas professionals including George Gorman

George states “We hold the firm belief that with the correct training, any competent industry professional can become proficient in dealing with a whole range of valve and Christmas tree issues – even in the world’s most hostile working environments. Ultimately, we are committed to raising the level of proficiency of those dealing with valves and Christmas trees in the subsea sector, to lay the foundations for successful field operation.

The company conducts on-site courses in Europe and the U.S. and just held a course in Houston in March. Details are found at:

http://www.valveinstitute.co.uk/index.php/about-us#sthash.kbvnJ6oh.dpuf

Look at the whole system—George Gorman of Valve Institute

George responded to questions posed by Bob McIlvaine and Ross Waters as follows:

Bob: We have been reporting on severe service valves. How do you define this term?

George: Service is defined in API 6A, so a severe service definition, (should one be required), needs to be recognized across the board and really belongs in a recognized valve standard. Please note severe service may not be the same as Critical Application, which potentially considers not only service conditions, but also the design of the whole piping system. We need to consider the effect of valve failure from an economic, functional and safety viewpoint. For example, a surface system sometimes allows a valve to be by-passed to allow replacement, whilst subsea valves rarely have this luxury.

He also addressed questions posed by Ross Waters of CGIS

Ross: What is a severe service valve?

George: If we understand service in terms of pressure, temperature and material class for the well-bore constituents, and operating conditions only** – we are not looking at the whole picture. For example, we recently had a standard design small bore MEG valve that jammed closed which threatened to shut down production (well needed MEG to flow) – so not severe service – but definitely a critical application. On the other side of the coin, we used a severe service (H2S and sand) Choke Valve – but with a subsea replaceable insert – so, yes, severe service but not such an ultra-critical item since it can be repaired during a normal intervention, unlike many other valves which would require the recovery of the entire 120-ton subsea module to repair.

** API 6A 1.3 Service conditions

Ross: Is zero leakage isolation possible?

George: In my experience, yes, particularly in the smaller sizes (below 2” ND) and especially with resilient seals.

Ross: What is the minimum information required to properly select a severe service valve?

George: We issue a comprehensive data sheet template to our clients with over 150 line items relating to valve and actuator requirements (subsea valves). Fundamental to getting the right valve is appraising the manufacturer of all pertinent factors relating to the project valve requirements. Severe Service or General Purpose? Let the manufacturer decide.

Ross: What special information is required to properly select a severe service valve?

George: A comprehensive Valve and Actuator Client Data Sheet.

Ross: How valid are factory seat tests when compared to actual application requirements?

George: Again, the data sheet can specify a required pressure and/or hold period over and above the minimum required by the relevant valve spec. to ensure the field conditions are replicated. For example, during pipeline pressure testing, the seats need to withstand a higher pressure than the valve rated pressure in order to be acceptable as a test barrier.

Ross: What are the advantages of separating your population of valves into Severe Service and General Purpose?

George: Personally, I would make the distinction between “bespoke” and “off the shelf.” The difference of course is standardisation (or not) of the design and the lead-time, which is always an issue when dealing with project schedules.

Ross: What valve types need to be mothballed?

George: All the types I have dealt with (Isolation, Flow Control, Choke, Directional Control, Instrumentation, Pressure Relief, Non-return, DBB, Bypass, Plug) performed their specific functions) I have not yet experienced a failure purely due to valve type – it is the client’s responsibility to accurately specify a valve that is fit for purpose.

George also had some comments on the interview with Muktiadi (Adi) Rahardjo of Shell

Adi: A tight shut off ball valve in particular will have a super tight gap between its sealing components.

George: As you are aware, the design calculations and FEA should be made at max and min temp. differential in order to produce an acceptable contact pressure distribution. Good sealing is not only the product of correct ball/seat tolerances, but also surface finish and seat pressure (and spring) end load.

Adi: Please note that dry sealing elements will cause higher friction and are prone to galling of components.

George: Correct application of appropriate coating will prevent this happening over the life of the valve.

Muktiadi Rahardjo of Shell has more advice to valve vendors

In the last Valve Insights, we summarized a Valve World interview of Muktiadi Rahardjo. He is the valve and sealing specialist at the Shell Pernis refinery and based on this experience recommends better communication relative to valve issues. Bob Mcilvaine asked Adi some more questions and we received his quick and detailed response.

Bob: We have been reporting on severe service valves. How do you define this term?

Adi: Valves for severe service application are any valves that should sustain or exceed an agreed period of lifetime in a super specific harsh environment and shall perform within agreed/tolerable measurable boundaries e.g. leakage rate, operable, speed of movement.

Bob: In a previous interview you referenced the need to better understand the zero-leakage concept. Can you provide an example?

Adi: It is interesting that many of the vendors claim to have a Tight Shut Off valve with Zero leakage. This may be right if the point of view was during in-house testing using hot (clean) gas/air and or water after hundreds to thousands of cycles. But I have to emphasize that the operational condition is way different either for treated or untreated products. Also, measuring bubbles on the downstream side of the valve is either impossible if not hard due to volume or other parameters.

TSO Metal to Metal valve falls into Leakage Rate Class B as per ISO 5208, which allows several bubbles per minute. Simply claiming “Zero bubble” is misleading to the end user and kills the spirit of improvement by other manufacturers.

Bob: Can you elaborate on this example?

Adi: A tight shut off ball valve in particular will have a super tight gap between its sealing components. At the wrong conditions, it may be prone to differential thermal expansion rates for components in contact with each other. I have experience with one of the suppliers claiming no bubbles in a SIL 2 classification. The ball valve was unable to move when required due to the fact that the ball heated up more than the body which remained colder due to the heat loss.

End users in general and especially for complex refineries have unique know how of materials’ and valve type selection. For instance, Stellite Hard facing is more prone to problems in amine service. PTFE is prone to swell in the presence of Ethylene Oxide (EO), Fossil based soft goods in addition to Non-exempted material are prone exothermic reaction for LOX (Liquid Oxygen) and GOX (Gaseous Oxygen) service. These are just some examples of the materials experience accumulated by large refineries.

Bob: Are there other examples relative to the need for information exchange?

Adi: Many manufacturers try to re-design the Rising Stem Ball Valve. Most fail, but some are indeed succeeding. In my humble opinion, the differences are minor. It is just some tweaking on how to do maintenance differently. This being the case it is unwise for the installation and operation manual to specify that maintenance without supervision will breach the warrantee.

Bob: What are the main drivers affecting your valve decisions?

Adi: In general end users are driven by two main things:

Regulations e.g. Fugitive Emission classification, HF Alkylation, UOP Phillips, etc. The future challenge is: can a valve be dry and clean enough (without fossil based soft goods and lubricant) to meet the standard and still have a competitive price. Also, can it perform within Fugitive Emission restrictions for the next 25 years? Please note that dry sealing elements will cause higher friction and is prone to galling of components. Also 25 years is standard valve lifetime in a refinery.

Suitable lifetime and delivery time of valves or its spare parts. The performance has to be sufficient to coincide with the expected down time in conjunction with other components e.g. pump, compressor, vessel, etc. Note: We do allow some leakage rate for most valves. In order to make it zero leakage, normally we use double barrier after the valve. End users have the need to minimize downtime. So, failures by valve manufacturers relative to support and maintenance should not be allowed.

If a valve fails spare parts and personnel who can repair it should be available within 1 to 3 days. 10 years ago, acceptable delivery time was 12 weeks, it is now moving towards 3-4 weeks or even earlier. That is why I advise well-known manufacturers to treat all customers as special. They should broaden their manufacturing network across the globe in order to achieve acceptable delivery time of spare parts and also spread their (basic) knowledge among end users.

Consensus must be reached between End user (Principal) and manufacturer stating that SSV will sustain xx years; within xxx threshold measurement level (leakage, speed, etc.); under proper operational workmanship and agreed process conditions.

Claims of “the best valves in the world, zero leakage and maintenance free” are suspect. It is like a well-known car manufacturer claiming to be the fastest without any chances of crashing. It is detrimental to the industry if unsubstantiated and unachievable claims are made.

This is not to say that progress toward this end cannot be made. But it requires good synergy between the manufacturer and end user, starting from the design phase and into operation (3-5 years until the warranty is void). My approach would be to always create a double jeopardy scenario. The valve eventually will fail, and another back up valve normally located downstream side should bear the load of the failing valve until rectification is completed.”

Ross Waters weighs in on the zero leakage and need for a SSV definition

Ross: I think the basic topic is still centred on Severe Service Valves and their definition. In Adi’s questioning, I too wonder why we are still using valve technologies that were invented in the industrial revolution. There is no valid reason to continue to use some of these basic valve types. Oil Companies including Shell continue to keep manufacturers in business by buying and using these products. It’s time to retire them.

Leakage for isolation valves is a performance based output. Not all valve types can perform the same way, either initially or over their required life cycle. The mystery is that the industry does not have a cohesive and effective way to provide this performance. We confuse factory tests with the needs of the valve in its application. Currently CGIS is conducting slurry cycle tests to obtain objective data on the number of dynamic cycles a slurry isolation can reasonably be expected to perform at a determined or maximum leakage rate.

In response to Bob McIlvaine’s suggestion that he organize a webinar with Adi, myself and others interested in the subject I submit the following topics for discussion:

1) What is a severe service valve?

2) Is zero leakage isolation possible?

3) What is the minimum information required to properly select a severe service valve?

4) What special information is required to properly select a severe service valve?

5) How valid are factory seat tests when compared to actual application requirements?

6) What are the advantages of separating your population of valves into Severe Service and General Purpose?

7) What valve types need to be mothballed?