GAS TURBINE INLET FILTER UPDATES

March 2020

- Recent Articles in IFN

- FILTXPO 2020

- GT Inlet Filter Coverage in Recent Utility E Alerts

______________________________________________________________________________

Recent Articles in IFN

McIlvaine, IFN and FILTXPO have been busy lately pursuing true cost information on gas turbine inlet filters. This includes articles in the two most recent issues of IFN plus lots of activity at FILTXPO and a gas turbine inlet filter tour guide at Power Gen in New Orleans

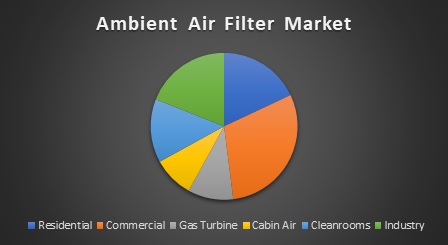

The January – February IFN carried the McIlvaine summary of the air filtration market including gas turbine inlet filters which are a significant percentage of the total ambient air filter market.

The full article is on the IFN website https://online.publicationprinters.com/html5/reader/production/default.aspx?pubname=&pubid=8f10051d-cbac-483f-b50e-51073e0e59bf

The November-December IFN included a true cost article on gas turbine inlet filters. It includes a pre FILTXPO guide to exhibitors with relevant media. This is being expanded in the coverage below on the actual event

https://online.publicationprinters.com/html5/reader/production/default.aspx?pubname=&edid=36240e8f-387a-4851-816f-2c2974d323a5

FILTXPO 2020

Despite the snowy weather and no shows due to the coronavirus FILTXPO was a success. Many of the exhibitors displayed products for gas turbine inlet filters. There were also some highly relevant speeches.

Air filtration is one of the many promising applications for nanofibers, according to Andrew McDowell, of NXTNO in his speech. For a given pore size, he said a nanofiber membrane can have two times the flux of a cast membrane. Nanofibers can be compoundable as hydrophobic, hydrophilic and other characteristics. Sterilization does not impact performance properties.

Filters are rated based on the particle size they are designed to remove from the environment. However, particles are not all spheres with the same specific gravity. During his presentation, R. Vijayakumar, president of Aerfil, highlighted this point by presenting graphs showing corrections for density and shape for use with optical particle counters. Therefore we must look to more practical approaches for rating filters.

At the Blue Heaven Technologies stand, the company’s president Bob Burkhead, spoke about Blue Heaven’s new rating tool, which incorporates a simulated room with air recirculating through a filter. The performance is based on multiple passes rather than a single pass. Since this is the way HVAC filters are used, it makes sense to use this kind of measurement in decision making. There has been a similar initiative at Donaldson. It utilizes a miniature fabric filter, which can be connected to a stack and determine actual efficiency directly. McIlvaine Company used a similar approach in developing a 1 cfm mini scrubber, which measures pressure drop needed to achieve a given emission level.

For gas turbine inlet filtration a miniature multistage inlet filter side stream system could be operated for extended periods and the results over time compared to the original results. Since there is a big difference in ambient contaminant levels depending on whether it is a platform in the North Sea, a desert oil extraction location, or a polluted industrial environment it is important to determine the right filter for a specific location.

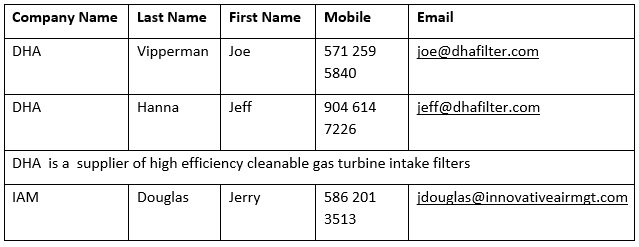

At the show we talked to an exhibitor Jerry Douglas of Innovative Air Management. He designed a cleanable HEPA filter using Shanghai Lingqiao media. The miniature test rig would be an ideal way for IAM to demonstrate the value of this new product.

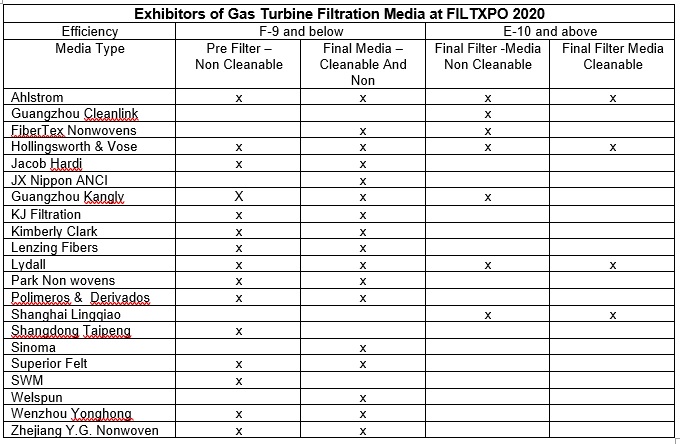

There were over 100 FLTXPO exhibitors prior to Coronavirus travel bans. However 22 Chinese companies were not able to participate. Nevertheless there were a number of exhibitors of filter media for gas turbine intake filters. They were segmented based on pre filtration versus final filtration and cleanable vs non cleanable

Ahlstrom, Hollingsworth & Vose had the largest stands. All three are supplying media for gas turbines.

Ahlstrom: A range of efficiencies for both static and pulsable filtration media were displayed. Cedric Vallet, filtration product manager explained the options.

Ahlstrom-Munksjö Trinitex® GTIs is a technology which offers filter media with excellent mechanical filtration efficiency and low pressure drop thanks to its unique 3-layer structure. Each layer can be customized to deliver specific properties and an optimal combination of strength, mechanical particle removal efficiency (even at small particle sizes) and pressure drop. Trinitex® is easy to process on rotary and knife pleating lines.

Ahlstrom-Munkjö Trinitex® Advance GT includes Trinitex® Advance: W3000 and W3200.

Ahlstrom-Munksjö Glass GT uses microglass technology to guarantee consistent efficiency in the final stage of air intake filtration – which ultimately protects the turbine. Microglass media is available in dual layer design, which provides increased dust holding capacity while maintaining the highest possible efficiency. Microglass media is purported to be the best option for static filter F7-F9 and HEPA filter applications.

Ahlstrom-Munksjö Nano GT consists of cellulose-synthetic media coated with electrospun nanofibers on the upstream side. This structure results in excellent reverse-pulsing behavior and high mechanical efficiency at the lowest possible pressure drop. Nano GT can also be customized with value-added treatments such as fire retardancy.

Ahlstrom-Munksjö FineFiber GT combines the advantages of cellulose synthetic media and fine fiber meltblown technology. It delivers a media with excellent reverse-pulsing properties as well as high dust holding properties for extended pulse cycles.

Ahlstrom-Munksjö CellTech GT is a blended media and is available in different basis weight and cellulose-synthetic ratios. It has good mechanical strength and pleating behavior on rotary machines and deep corrugation offers optimum pleat separation.

Ahlstrom-Munksjö Synthetic GT Is a based on the CellTech platform with a fully synthetic fiber composition and a hydrophobic treatment. The self-supported structure is designed for pulse-jet applications, combining pleatability, excellent durability and very good performance for filtering coarse particles.

Hollingsworth & Vose: We talked to Joh Ayers, Division President of Engine and Industrial on a range of subjects including gas turbines. A new line of NANOWEB®-coated filter media has been specifically designed to meet the growing needs in gas turbine/dust collector air filtration. NANOWEB technology offers 0.3 to 0.5 micron nanofibers. Unlike electrospun nanofibers, NANOWEB fibers are stronger and more durable so the nanofiber coating can withstand stringent pulse-cleaning forces.

The new NANOWEB filter media offers significantly improved fractional efficiency over untreated substrates (97% versus 90%) when tested against AC fine test dust. When tested with 0.3 to 0.4 micron of NaCl particles, which are similar to soot, NANOWEB coated media has 60% fractional efficiency as compared to 20% with standard untreated media. Not only does NANOWEB coating greatly improve equipment protection, it also extends filter life and service intervals.

The cleanable line of NANOWEB filter media is specifically designed to meet the stringent pulse-cleaning requirements. Unlike other fragile nanofibers, NANOWEB coating exhibits increased media adhesion and more durable nanofibers. These stronger nanofibers offer a significant increase in pulse lifetime compared to untreated substrates. The high surface area of NANOWEB coating also noticeably improves the dust cake release during cleaning.

Lydall: We had multiple conversations with personnel including with Paul Marold, president of Lydall Performance Materials. He was co-chair of the conference. Michael O’ Laughlin, vice president of Advanced Solutions in his speech talked about developing technology in gas phase and particulate collection.

Arioso® high performance air filtration composite media, according to the stand personnel, is ideally suited for gas turbine air intakes, where end users value high efficiency filtration for reduced cleaning, less downtime, and maximum energy output. Suitable for pulsed and static applications, Arioso media delivers E10 to E12 efficiency at low resistance. Arioso composites’ resistance to oil and hydrocarbon loading provide longer filter life than other available membrane technologies.

Exhibiting excellent dust release in a highly durable membrane, Arioso composites can be used in both pleated cartridges as well as sewn or welded bag applications. At half the pressure drop of microglass filtration media for a given efficiency, Arioso composites are said to deliver lower energy consumption in clean space applications.

GT Inlet Filter Coverage in Recent Utility E Alerts

Utility E Alert November 15, 2019 Pre-show Coverage of PowerGen -New Orleans

The McIlvaine Company is working with associations, media and suppliers to create true cost analyses of combust, flow and treat products and services. One such initiative is the “True Cost of Gas Turbine Inlet Filters.”

The true cost of a gas turbine inlet filter can be affected by a large number of factors. These factors are not constants but are changing. The filter purchaser is challenged to not only identify these factors but to keep up with the changes.

Large gas turbines are used to generate electricity by utilities. Smaller gas turbines, drive pumps and compressors in locations with extreme conditions such as desert dust, artic snow or sea spray on an oil rig. As turbines have become more efficient, they have become more susceptible to damage from contaminants in the combustion air. This ambient air from the surrounding environment can contain high dust loads. In California, with very tight emission standards, the particulate in the inlet air to the turbine can exceed emission limits. Thus, the gas turbine has to act as an air cleaning device.

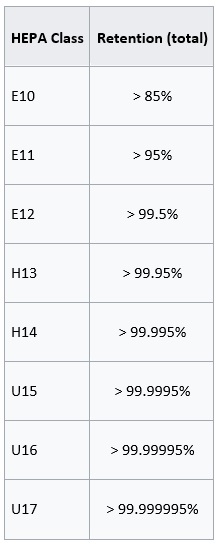

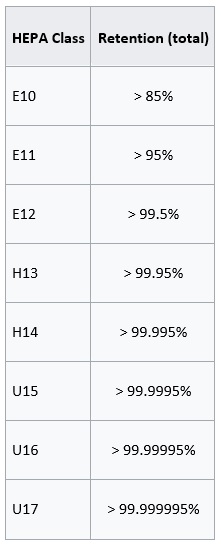

The challenge for gas turbine inlet fiber, media, and filter suppliers is to increase gas turbine availability in all environments with newer and more sensitive gas turbines. The newer turbine designs are negatively impacted by small particles. This has led to the use of HEPA filters with efficiencies classed as H10/E10 and higher. Studies show that turbine maintenance can be reduced with even higher efficiency E12-U17. One study showed that even if the cost of higher efficiency filtration were four times higher than lower efficiency filters, the true cost would be lower.

One can choose a system with non-cleanable filters. They are relatively inexpensive but require continuous filter replacement. By using a sequence of inefficient but inexpensive pre filters and a final high efficiency filter, the replacement cost can be minimized.

An alternative is to use a cleanable filter. Periodic air pulsing knocks off accumulated dust. These systems are available from many suppliers if the F-9 efficiency is all that is desired. Cleanable filters with H12 efficiency are available from only a few suppliers. On the other hand, there are many new developments which will expand the number of choices.

In terms of high efficiency dust capture mechanisms there is a choice between wet laid glass and synthetic nanofiber non-woven laminates or membranes. The traditional glass media for HEPA filtration has been used primarily in non-cleanable filters.

Quantifying the benefit is a balance between reduced fouling and increased pressure drop. The increased pressure drop can be estimated to restrict performance by approximately 0.4%, while cutting fouling provides a 1.2% improvement in output (empirical average). Therefore, the overall result is a potential efficiency improvement of 0.8%.

http://www.mcilvainecompany.com/GTairTech/Subscriber/Default.htm

Alliance Pipeline believes that the E12 filters from Gore may allow Alliance to extend the interval between overhauls of its aero engines from 25,000 to as many as 50,000 hours (from three to six years).

The many factors and media choices impacting gas turbine inlet filter selection have been discussed in a background document on display at

http://www.mcilvainecompany.com/Decision_Tree/subscriber/Tree/DescriptionTextLinks/Gas_turbine_inlet_filter_decision_guide_april_26830.pdf

In the past the most efficient filters that were used on gas turbine inlets were rated F-9 with efficiency of more than 95% on particles 0.4 um diameter. The most penetrating particle size is about 0.2 um where the efficiency is much lower. Higher efficiency filters are rated based on the most penetrating particle size as follows:

Membrane laminates such as used for dust collection can meet efficiencies up to E12. The question is whether this is sufficient?

There are a number of new filter and media designs, which need to be evaluated. Mann & Hummel Vokes introduced the Aircube Pro Power S, which utilizes a new synthetic base media with much higher resistance to mechanical stress than glass fiber media and a stable high efficiency during operation. It is water and salt repellent while being extremely robust.

DHA Filter has introduced a cleanable HEPA filter for gas turbine inlets, which it will be displaying at Power-Gen.

Utility E Alert November 8

DHA is introducing a New Gas Turbine Inlet Filter at Power-Gen As the costs and complexity of gas turbine generators increase, end users seek ways to both protect and maximize their investment. Many gas turbine operators have explored high efficiency options for their inlet filters. Switching to HEPA grade intake filtration greatly reduces the presence of contaminates in the turbine compressor. This helps extend turbine life and efficiency while reducing the costs in fuel and maintenance. There have been a few drawbacks to making the move to HEPA filters. One issue is that with a more restrictive filter media comes increased initial pressure drop. There have also been questions surrounding the long-term durability and lifespan of the HEPA filters.

November 15 Gas Turbine Inlet Filter – True Cost Investigation

Speeches: None are directly applicable although Mitchell Krasnopoler of Kiewit will be speaking about air emissions and can address the fact that with HEPA filter gas turbine inlets the outlets are reduced below requirements in California where ambient air levels exceed emission limits.

Stands: The only stand displaying gas turbine inlet filters is DHA stand 1331. An open meeting at their stand is scheduled for 10:AM Wednesday but check updates for changes.

Issues to be Discussed: DHA will be displaying a rugged cleanable HEPA filter. The debate has centered on whether the theoretical value of lower maintenance with the HEPA filter is worth the higher cost. The argument against the HEPA filter has been fragility. (see separate analysis)

As the costs and complexity of gas turbine generators increase, end users seek ways to both protect and maximize their investment. Many gas turbine operators have explored high efficiency options for their inlet filters. Switching to HEPA grade intake filtration greatly reduces the presence of contaminates in the turbine compressor. This helps extend turbine life and efficiency while reducing the costs in fuel and maintenance. There have been a few drawbacks to making the move to HEPA filters. One issue is that with a more restrictive filter media comes increased initial pressure drop. There have also been questions surrounding the long-term durability and lifespan of the HEPA filters.

The true cost of a gas turbine inlet filter can be affected by a large number of factors. These factors are not constants but are changing. The filter purchaser is challenged to not only identify these factors but to keep up with the changes.

Large gas turbines are used to generate electricity by utilities. Smaller gas turbines, drive pumps and compressors in locations with extreme conditions such as desert dust, artic snow or sea spray on an oil rig. As turbines have become more efficient, they have become more susceptible to damage from contaminants in the combustion air. This ambient air from the surrounding environment can contain high dust loads. In California, with very tight emission standards, the particulate in the inlet air to the turbine can exceed emission limits. Thus, the gas turbine has to act as an air cleaning device.

The challenge for gas turbine inlet fiber, media, and filter suppliers is to increase gas turbine availability in all environments with newer and more sensitive gas turbines. The newer turbine designs are negatively impacted by small particles. This has led to the use of HEPA filters with efficiencies classed as H10/E10 and higher. Studies show that turbine maintenance can be reduced with even higher efficiency E12-U17. One study showed that even if the cost of higher efficiency filtration were four times higher than lower efficiency filters, the true cost would be lower.

One can choose a system with non-cleanable filters. They are relatively inexpensive but require continuous filter replacement. By using a sequence of inefficient but inexpensive pre filters and a final high efficiency filter, the replacement cost can be minimized.

An alternative is to use a cleanable filter. Periodic air pulsing knocks off accumulated dust. These systems are available from many suppliers if the F-9 efficiency is all that is desired. Cleanable filters with H12 efficiency are available from only a few suppliers. On the other hand, there are many new developments which will expand the number of choices.

In terms of high efficiency dust capture mechanisms there is a choice between wet laid glass and synthetic nanofiber non-woven laminates or membranes. The traditional glass media for HEPA filtration has been used primarily in non-cleanable filters.

Quantifying the benefit is a balance between reduced fouling and increased pressure drop. The increased pressure drop can be estimated to restrict performance by approximately 0.4%, while cutting fouling provides a 1.2% improvement in output (empirical average). Therefore, the overall result is a potential efficiency improvement of 0.8%.

http://www.mcilvainecompany.com/GTairTech/Subscriber/Default.htm

Alliance Pipeline believes that the E12 filters from Gore may allow Alliance to extend the interval between overhauls of its aero engines from 25,000 to as many as 50,000 hours (from three to six years).

The many factors and media choices impacting gas turbine inlet filter selection have been discussed in a background document on display at

http://www.mcilvainecompany.com/Decision_Tree/subscriber/Tree/DescriptionTextLinks/Gas_turbine_inlet_filter_decision_guide_april_26830.pdf

In the past the most efficient filters that were used on gas turbine inlets were rated F-9 with efficiency of more than 95% on particles 0.4 um diameter. The most penetrating particle size is about 0.2 um where the efficiency is much lower. Higher efficiency filters are rated based on the most penetrating particle size as follows:

Membrane laminates such as used for dust collection can meet efficiencies up to E12. The question is whether this is sufficient?

There are a number of new filter and media designs, which need to be evaluated. Mann & Hummel Vokes introduced the Aircube Pro Power S, which utilizes a new synthetic base media with much higher resistance to mechanical stress than glass fiber media and a stable high efficiency during operation. It is water and salt repellent while being extremely robust.

DHA Filter has developed a new line of intake filters that address many of these

concerns. DHA’s Duraweb™ Elite line features a new 3-layer media that combines high efficiency filtration with durability and breathability. The base layer is a 100% synthetic material that gives the media pack its strength and enable the filter to be pulse cleanable. The 2nd layer is a thin “relaxed” ePTFE membrane. The membrane is what gives the filter its high E11 efficiency while maintaining a low initial pressure drop. The physical properties of this membrane repel water and dust ensuring maximum filter life. Finally, a synthetic top layer adds dust holding capacity while protecting the membrane. The media is hydro- and oleophobic which helps it to perform in environments where hydrocarbons and/or high humidity are present.

DHA’ Duraweb™ Elite line features a new filter media that uses 3 layers to prove HEPA grade inlet filtration:

1. The fully synthetic top layer adds dust holding capacity and protects the membrane. This layer is treated to be oleophobic and hydrophobic to repel hydrocarbons and moisture.

2. A very thin “relaxed” ePTFE membrane gives the filter an E12 efficiency while maintaining a low initial pressure drop. This membrane is applied with a proprietary process that ensures durability and maximum filter life.

3. The synthetic base layer is made from a robust material that provides strength for the media pack. This allows the filter to hold up over time even after going through numerous pulse cleaning cycles.

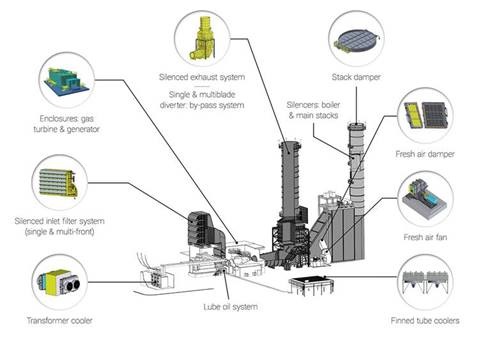

Boldrocchi is offering complete systems including gas intake filters.

Background Information In Gas Turbine Decisions (Free To Operators)

Gas Turbine Intake Filters Webinar - Hot Topic Hour May 21, 2015 The session covered four route maps in the Gas Turbine Combined Cycle Air Treatment Guide

Nonwovens in Gas Turbine Air Filtration Clarcor offers a full range of air inlet filters for gas turbine applications including panel, pocket V-cell and cartridge filters. This presentation addresses ways to improve inlet filtration to avoid fouling and corrosion of turbine equipment.

Gas Turbine Air Filter System Optimization Proper air filtration is critical to the overall performance and reliability of gas turbines. This article discusses various aspects of the air filtration and conditioning process including inlet cooling, filters and water wash cycles.

Gas Intake Filters: HEPA or Medium Efficiency Webinar - Hot Topic Hour May 15, 2014 A high level discussion attended by knowledgeable end users, consultants, fiber makers, media suppliers and filter manufacturers.

EMW recommends HEPA filters for air intakes to reduce compressor cleaning A new trend is emerging in the sector of gas turbine inlet air filtration. Frequently, highest-efficiency (H)EPA filters are selected as the solution of choice for optimum protection of gas turbines. A leader in (H)EPA technologies for many years, EMW offers comprehensive product solutions to keep your gas turbine plant at the cutting edge.

HEPA Air Filtration Technology Keeps Compressor Blades Clean Combustion turbine operators generally experience turbine fouling from airborne particles passing through existing inlet air filters. Fouling can be caused by the particle capture limitations of conventional F-class (EN779:1998) or MERV-class (ASHRAE 52.2) filters. The consequence is reduced performance of the turbine operation.