NEWS RELEASE JANUARY 2017

IIoT is Creating New Market Paths to the $100 Billion Gas Turbine Repair, Replace and Service Market

The Industrial Internet of Things (IIoT) is a powerful new force shaping the way gas turbine products are purchased. The impact of IIoT is being continually assessed in 59EI Gas Turbine and Reciprocating Engine Supplier Program.

The inventory of existing gas turbine plants is growing at six percent per year and in the next few years the base will grow to two million MW. There are 30,000 individual units which routinely require service, replacement or repair of instrumentation, valves, pumps, filters, nozzles, and other components. There is a continual need for filter elements, treatment chemicals, lubricants, catalysts, reagents and other consumables. The market for replacement products, repair and services is $100 billion per year and will grow by more than six percent per year

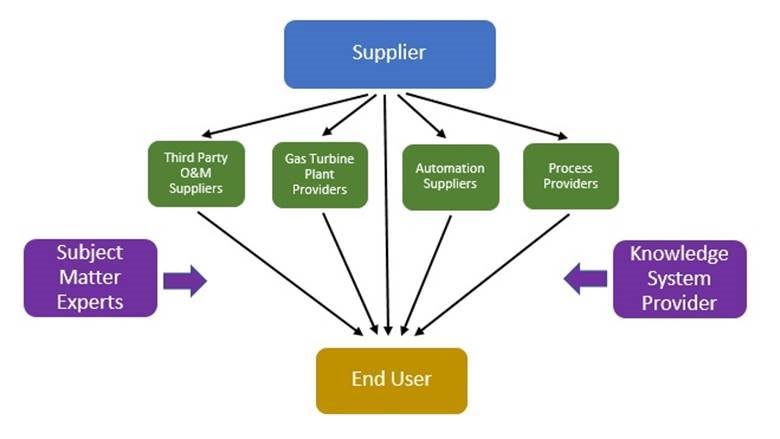

IIoT provides remote delivery of comprehensive information about the operation and health of individual components. This data can be analyzed to identify problems and will create opportunities for the sale of better products to replace the existing ones. IIoT is creating new channels to market in contrast to the sale of products directly to a single end user.

End Users

Large end users are creating fleetwide purchasing and monitoring systems. Southern Company operates over 280 power generation units at 73 power plants including gas turbine, combined cycle, steam (coal), hydro and solar. Southern Company implemented the first phase of their fleetwide monitoring and diagnostics (M&D) center in 2007.

Duke Energy is growing its fleetwide monitoring and diagnostics center. Duke’s efforts promise to result in maintenance savings and availability improvements, while increasing equipment health visibility and optimizing logistics of maintenance.

The one hundred largest operators of gas turbines around the world account for the majority of purchases. Therefore, working with them should be a high priority. Each of these plants is identified in Gas Turbine and Reciprocating Engine Supplier Program.

Gas Turbine Plant Providers

Gas turbine suppliers have remote monitoring centers primarily focused on the health of rotating parts such as turbines. However, this is being expanded. MHPS just opened a remote monitoring center in the Philippines. It is monitoring the balance of plant in addition to the turbines.

Process Providers

Suppliers of heat recovery steam generators, ultrapure water, emission controls and water treatment are also purchasers or influencers relative to products. Nalco has a water quality remote monitoring center which operates around the clock.

Automation Suppliers

ABB can provide all required gas turbine control and protection functions utilizing the very same ABB DCS platform that controls the rest of the plant. The typical gas turbine functions implemented include fuel control, startup sequence, speed-load-temperature closed loop control, overspeed protection, anti-surge protection, generator protection, auxiliary control, condition monitoring, auto-synchronization, excitation, frequency control, etc.

Yokogawa has various programs including one which monitors the wastewater from the plant. The automation supplier can be working directly with the end user and not necessarily through the process supplier.

Subject Matter Experts

When problems arise, which cannot be handled by the dedicated supplier personnel, it is necessary to turn to subject matter experts. A product problem for one supplier can turn into an opportunity for another as a result of the recommendations of a subject matter expert. Product suppliers need to encourage the participation of subject matter experts who understand the product and can provide lowest total cost of ownership advice.

Knowledge System Providers

Emerson’s use of Seek software allows incorporation of insights and background data which can be opportunistically displayed to help solve problems as they occur.

The gathering and organization of this data for use in the software system is a major challenge. McIlvaine is providing this data in its gas turbine related services but also in systems structured for a single utility. The beta site is for Berkshire Hathaway Energy (BHE) which operates hundreds of gas turbine and other power plants.

O&M Third Party Providers

Many gas turbine combined cycle plants are operated and maintained by third parties. The developments in remote monitoring are making it more attractive to sub contract to a company specializing in O&M. These providers include specialized service companies such as Wood Group and EthosEnergy, power plant operators such as Uniper and RWE who are leveraging their experience to help others, and the plant suppliers such as Siemens and GE who have build/own/operate (BOO) contracts.

Suppliers have an opportunity in an expanding gas turbine market to take advantage of the IIoT driven changes and to increase not only revenues but gross margins and profits as a percent of those revenues. This will require direct high level communication with several types of organizations.

For more information, click on 59EI Gas Turbine and Reciprocating Engine Supplier Program