NEWS RELEASE AUGUST 2014

Upgrading Coal Plants around the World Is the Best and Quickest Way to Reduce CO2

The reality is that coal will remain a major fuel source for electricity generation for the next several decades. Coal generators will continue to be the leading source of CO2 emissions. Making these plants more efficient is the easiest way to reduce not only CO2 but all the pollutants. The cost and benefits of an efficiency improvement program are provided in the McIlvaine report, Fossil and Nuclear Power Generation: World Analysis and Forecast.

A new study from IEA released in July 2014, cites the Chinese example as the model. The Chinese are now anticipating an economic plant life of 25 years as opposed to 40 years used as the EU model and even longer in the U.S. China is replacing small old plants with new ultrasupercritical designs. These designs all have the latest air pollution control equipment. China realizes that technological improvements make existing plants obsolete after 2.5 decades. Who would argue that the economic life of an automobile is more than 25 years?

IEA points out that a 25-year economic life model completely changes the priorities for CO2 reduction in many countries of the world. This is particularly true for the U.S. which has the oldest coal fleet.

The “Clean Power Plan” just announced by U.S. EPA relies on improving energy efficiency at old coal-fired power plants. That is the equivalent of trying to make a sixty year old gas guzzler as efficient as a 2014 model hybrid. The clear choice is to scrap the gas guzzler and buy a new car. This is also the obvious way to meet the EPA goals relative to coal-fired power. In fact, the new coal-fired power plant solution is a win-win situation for all sides because:

- The environmental goals are exceeded,

- There is a big stimulus to the U.S. economy,

- Electricity rates are lower than with any other plan,

- Because of the twenty-five year optimum life of a coal-fired power plant, there will be a whole new set of options in 2045.

- Use of vertical space. The average power plant already has stacks many hundreds of feet high. Kiewit has an innovative use of the grain tower design to build 80 foot diameter modules which are 400 feet high. So innovations such as this will result in cost effective upgrades.

- Upgrades/replacements are more efficient and, therefore, produce more electricity for a given footprint.

- Use of new technology such as catalytic filters. This filter combines particulate filtration and NOx reduction in one unit greatly reducing space requirements and retrofit costs.

- Use of treated municipal wastewater for cooling and other purposes. Nearly all existing power plants are within 70 miles of enough treated municipal wastewater to supply their water needs.

- Zero liquid discharge systems. Upgraded power plants will not have water discharges.

- Co-generation and reduction of emissions from other sources. Great Rivers Energy has Blue Flint ethanol plant on-site. The ethanol plant has no boiler and no emissions since it uses waste heat from the power plant.

- Supplementing coal with other fuels for optimum cost and environmental improvements. Gasified municipal waste and biomass can be used as re-burn fuels to reduce NOx.

Since all sides benefit, there is every reason for agreement, fast track siting of new power plants and simultaneous retirement of old power plants.

The “Clean Power Plan” proposed by the Obama Administration seeks to achieve a 30 percent reduction in CO2 emissions from existing electric generating units by 2030 based on a 2005 baseline. States must show “meaningful progress” by 2020. With a strategy of coal-fired power plant replacement, this progress and compliance with the timelines will be assured.

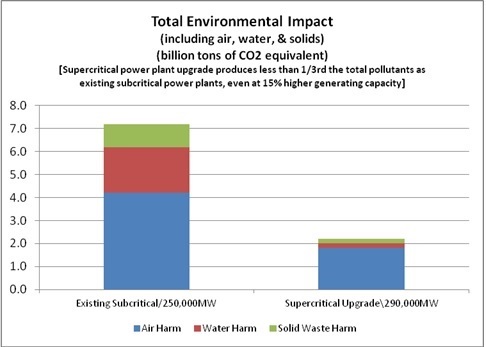

The air pollution impact of upgrading the old fleet to supercritical efficiency would be a reduction equivalent to 2.4 billion tons of CO2. The validity of this calculation is easily determined by using the EPA cost justification values. CO2, various air toxics and each criteria pollutant is assigned a monetary value, so this creates a common metric. There are other environmental benefits. The upgraded coal-fired power plants would not generate the water and solid waste caused by the old power plants, so total environmental impact would be the equivalent of 5 billion tons of CO2.

For more information on Fossil and Nuclear Power Generation: World Analysis and Forecast, click on: http://home.mcilvainecompany.com/index.php/markets/2-uncategorised/113-n043