NEWS RELEASE May 2024

Industrial Pump Market to Reach $100 billion by 2034

Whether it's mixing drying evaporation or liquid treatment, pumps are a key element in the process.

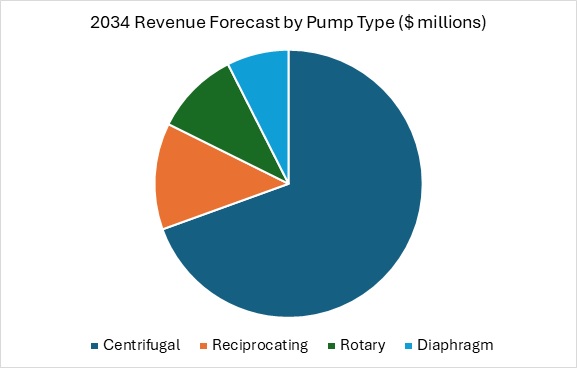

The split in 2034 by pump type will be as follows.

The market share for critical and severe service will increase while the market for general service will decrease.

The market for severe service pumps is increasing in a number of applications. One is hydraulic fracturing. This has taken over the oil and gas production in the United States and promises to be a big application in Argentina China, and other countries. The pumps wear out very quickly and parts are replaced sometimes, as often as every few weeks. So, hydraulic fracturing is at the very top of the list of severe service applications.

Critical service is also expanding at the expensive general service. Critical service includes the sanitary pumps that are used at hygienic applications in the food and pharmaceutical industry, where no contamination of the product can be tolerated.

There are some pumps that are classified under both severe service and critical service but are included for statistical purposes in the severe service category. One example would be pumps for chocolate. This is a very viscous liquid and is a severe service application but as a food it is also a critical application.

A new category is single use pumps in cell gene therapy. The cost of cleaning a pump between batches is significant and justifies the actual use of a pump with replaceable single use parts.

Pump use for hydrogen production is expanding. It has several aspects. One is using electrolyzers to generate electricity and converting water to hydrogen. This requires water to make the hydrogen provided by pumps which also need to overcome the pressure pressures of reverse osmosis.

Once the hydrogen is formed, it must be liquefied and transported, and this is a tough application for pumps and the need for very superior seals.

The mining industry uses a number of pumps for the processes, but also in many remote mines the ore is liquefied with a slurry and pumped to the ocean for transport. So, there are very large pumps moving ore long distances.

The industry is changing in a number of ways distributors are making skids and shipping those skids to the end-user. Those skids contain the pumps and valves and save a great deal of time and expense for the end-user.

There is a trend towards synergistic product offerings. Ingersoll Rand and Atlas Copco are buying pump valve and compressor companies and are able to furnish all of the products together in a package.

The pump market is most accurately assessed by understanding the process equipment to which the pumps are applied.

Example, in large cofired power plants capturing CO2, limestone is the common reagent. Pumps circulating as much as 400,000 GPM of gypsum slurry are required. Alternatively, the power plant can elect to use lime rather than limestone. This cuts the size of the pumps in half. This is a very large application for repair parts and a database of all the power plants in the world is utilized to more accurately assess the size of the replacement market.

Another big pump application is desalination. The water needs of the earth keep increasing and desalination is increasingly being relied upon to provide the freshwater needed.

More information on Pumps World Markets click on https://home.mcilvainecompany.com/index.php/markets/water-and-flow/n019-pumps-world-market