NEWS RELEASE December 2018

Product Forecasts for Each Customer as the Foundation of a Business Program

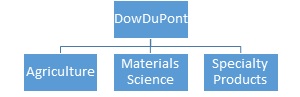

Large multi division corporations have the potential to pursue each potential customer using bottoms up collaboration. DowDuPont is used as an example of how McIlvaine recommends this opportunity be maximized.

DowDuPont is separating into “three intended strong companies which will be better positioned to reinvest in science and innovation, solve our customers’ ever-evolving challenges, and generate long-term returns for our shareholders,” according to Ed Breen CEO of DowDuPont. A major initiative will be to capture the synergies to unlock value. Breen continues “With clear focus, market visibility and more productive R&D, each intended company will be equipped to compete successfully as an industry leader.”

The challenge is overcome a global business structure which is filled with silos, fiefdoms, and disorganized approaches to making purchasing decisions. There is much discussion and accelerated leveraging of the Industrial Internet of Things (IIoT). Even though subject matter experts are thought to be important to the success of IIoT, there has been little effort to interconnect knowledge and people in an organized way. The needed structure is the Industrial Internet of Wisdom (IIoW).

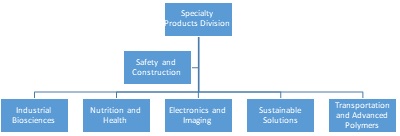

For DowDuPont this would involve the interconnection of people in the new organization. There is a big bottoms up opportunity in Safety and Construction. Here is where this division fits in the three soon to be new companies.

Safety and Construction is part of Specialty Products.

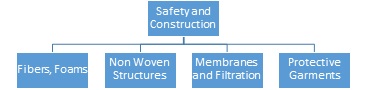

Protective garments, membranes and other materials and products relevant to

combust, flow and treat (CFT) are part of Safety and Construction

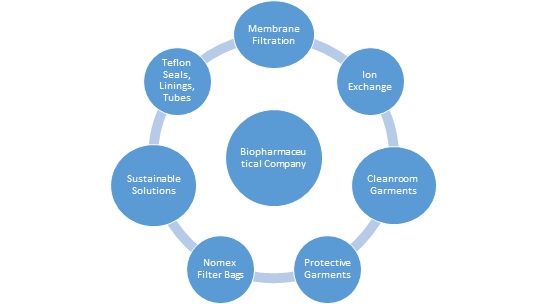

The McIlvaine Company has been working with various Dow and DuPont divisions on CFT related endeavors for 44 years and realizes the challenges of creating synergy among divisions. McIlvaine concludes that the answer is not a centralized effort from the top down but a decentralized effort from the bottom up. This bottoms up strategy centers around each individual large corporate purchaser. One example would be a biopharmaceutical manufacturer who has ultrapure water processes, cleanrooms, and lots of equipment using linings, tubes, and components made of or using DowDuPont products.

Information about the present and future processes associated with any biopharmaceutical manufacturer are no longer difficult to find. The filtration and pharmaceutical publications are filled with articles which are accessible in on line archives at no charge. Air, water, and other emissions from each plant are available with details down to the description of any piece of equipment which could potentially be an environmental or safety hazard. LinkedIn provides contacts and job descriptions of the key decision makers.

The application engineers and sales people in each DowDuPont division can collaborate around each major customer without much direction from above. Their goal should be to show that for a particular plant DowDuPont has the products with the lowest total cost of ownership. This lowest total cost of ownership validation (LTCOV) needs to be continuous and be based on the site-specific conditions at each plant.

The cleanroom garment use will be determined by the balance between isolators and ballroom cleanrooms or possibly the elimination of cleanrooms through closed continuous single use processes.

New plastics that offer adequate performance for single use and are documented to be as comparably risk-free as stainless steel are likely to be widely used in the biopharmaceutical industry. If documented or perceived as safer than current legacy plastics, they will be used. That provides a strong incentive for improved polymers/plastics development. Candidates include Teflon, and Elvax from Dupont and Dowlex and Engage from Dow.

If a new plastic product from DowDuPont makes single use systems more attractive the plant may incorporate them into a Class 10,000 cleanroom rather than a Class 1000 room. This would reduce the need for cleanroom garments. The product options are multiplied by the newest concepts for multipurpose facilities with both research and pilot size operations as well as full production of multiple drugs.

DuPont Sustainable Solutions has a long history of analyzing operations from the safety perspective. Safety is of high importance in biopharmaceutical manufacturing. Even the smallest doses of cytostatic agents have an irreversible and cumulative effect. The lowest total cost of ownership for cleanroom garments is substantially impacted by the protection offered from various Tyvek materials. Likewise, the garment design with proper neck and wrist seals is important. Safety is a consideration in the choice of materials for valves, pumps, tubing and other devices using DowDuPont products.

The building blocks to success are

- Identify the customer and the potential market for each DowDuPont product

- Create a collaborative structure to influence the decision makers at that company

- Create lowest total cost of ownership analyses for each product

- Validate the LTCOs with high level contacts at the company

The McIlvaine Company offers a program which will provide the market forecasts for each customer for each product. It also can assist with lowest total cost of ownership analyses. With webinars and other initiatives McIlvaine can help provide continuous validation.

For more details on the program Click Here

Bob McIlvaine can answer your questions at This email address is being protected from spambots. You need JavaScript enabled to view it. 847 784 0012 ext. 122