NEWS RELEASE April 2020

Billion Dollar Meat Processing Virus Mitigation Market

Meat processing plants have been deemed essential and yet much of the production has been terminated due to the coronavirus. There is a need to introduce the latest and best mitigation technologies to help these plants resume operations.

McIlvaine Company has a program to help suppliers and purchasers select the best products and services for safe but cost effective operations.

The global meat market was slated to pass the trillion dollar sales level this year but revenues will be down due to the virus. Meat companies could justify spending 0.1% ($1 billion) to 1% ($10 billion) of the revenues annually to insure that workers are safe and production continues. An initial capital investment of $20 billion or more with a 20 year depreciation period can be justified.

The U.S. market exceeds $200 billion/yr justifying an initial investment of $4 billion and annual expenses of $200 million to $2 billion per year to provide an alternative to periodic lockdowns.

To put the potential into perspective with other opportunities, there are 3.8 million nurses in the U.S and 19 million worldwide. Twenty-one million people work in the U.S food chain or seven times the number of nurses.

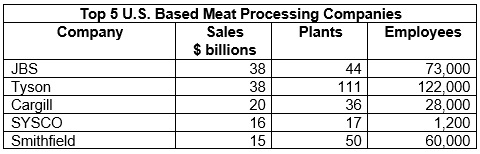

Over 500,000 people work in the animal slaughtering and processing industry in the U.S. 331,000 are in production. The top 100 U.S. based meat processing companies employ more than 500,000 people but many are not in the plants. Nevertheless office workers will need to be protected as well.

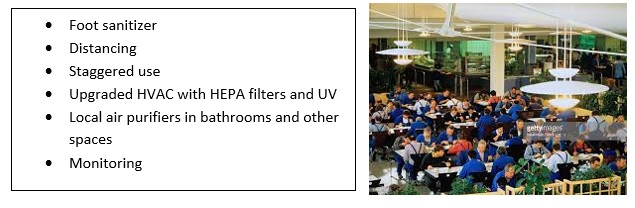

These processors have been deemed essential and have continued to operate. However many of the plants are now temporarily closed due to COVID-19 outbreaks. Over 600 workers at the Smithfield plant in South Dakota have contracted the virus. Crowded locker and lunchrooms allowed widespread transmission.

The industry is facing a huge problem but has the opportunity to be proactive and not only allow safe working conditions for employees but to reduce risk of product contamination. An additional benefit is to improve product quality. Studies have shown that cleaner environments can result in the extension of pork shelf life by 12 days. Here are some of the mitigation technologies which can be employed.

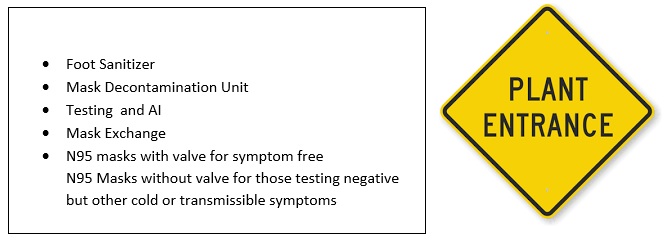

Plant Entrance

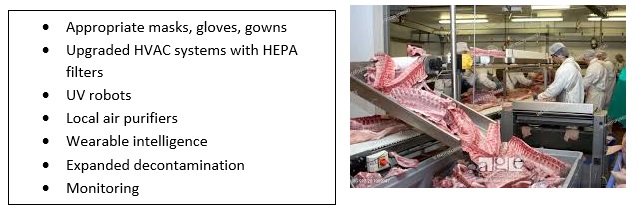

Plant

Offices, Lunch and Locker Rooms

Suppliers should keep in mind that there are many new technologies which will find widespread use. Nanofiber membranes offer higher efficiency and comfort in masks. Robots can monitor conditions as they move throughout the plant. Viruses have been proven to be transmitted by shoe soles. So there are now foot sanitizers.

Suppliers will not only have to deal with new technologies offered by their competitors but to international competition. China has decided that it must modernize and revamp the meat processing industry. It is offering incentives to develop improved and safer processing solutions.

Market and technology developments are included in Daily Alerts. Industry interface is created with webinars and analyses. Market forecasts are continually updated in Coronavirus Market Intelligence Click here for more information

Bob McIlvaine can answer your questions at This email address is being protected from spambots. You need JavaScript enabled to view it. cell 847 226 2391