NEWS RELEASE February 2017

Ultrapure Water Market bolstered by IIoT will exceed $12 billion in 2026

The market for ultrapure water systems and components will exceed $12 billion in 2026 according to the latest McIlvaine forecasts. This includes $2 billion of IIoT related products and services supplied by ultrapure water system and product manufacturers. In addition, $2 billion of ultrapure water products previously sold directly to operators will now be sold to third party O&M companies. As a result, there will be a $4 billion market shaped by IIoT.

|

Ultrapure Water System and Component Market 2026 |

||

|

Total Market |

IIoT Related Market |

|

| Power | 5 | |

| Electronics | 4 | |

| Pharmaceutical and Other | 2 | |

| Additional IIoT Revenues | 2 | 2 |

| Rechanneled Revenues | 2 | |

| Total | 13 | 4 |

A supplier of pumps, filters, valves, piping, treatment chemicals, or instrumentation has the opportunity to boost revenues. A smart pump or valve needed to communicate with the cloud is worth more than a dumb one. Suppliers of water treatment chemicals such as Nalco can boost sales with remote monitoring services.

These suppliers will also find that part of their market once served directly will now be served through third parties, so identification of new potential purchasers and specifiers is important.

System suppliers are one potential revenue source. MHPS, Siemens, and GE already have remote O&M services for turbines. It is very likely that one or more will expand into O&M for the related ultrapure water systems. Suppliers of pharmaceutical and semiconductor manufacturing equipment will also expand their offerings with IIoT.

A UPW supplier may also move into the broader O&M role. Danaher is moving aggressively into IIoT. The company supplies Pall filters, Hach water monitoring and Chemtreat treatment chemicals, so it could take on a larger role and possibly partner with valve and pump companies to provide integrated O&M.

3M is another candidate. 3M products for ultrapure water, include Pre-RO, Resin Trap, Point-of Use Pre-Filtration, and Point-of-Use Final Filtration. Degasification membranes are also supplied. 3M has installed sensors on its ScaleGard Blend Series of water filtration products. ScaleGards are typically used at restaurants to purify the water for soda machines. By digitizing the water systems, the restaurant managers receive alerts on their computers or mobile phones when a part on the machine needs to be replaced. The system also automatically sends an alert to 3M channel partners, letting them know when to deliver the replacement part.

3M's Active Safety software lets plant managers track safety issues on the production line. They attach an RFID tag to each piece of personal protection equipment, so managers can keep tabs on who's wearing what device, whether they are properly trained and if the equipment is in compliance with regulations. So, expansion into a broad IIoT role is a possibility.

Another group are O&M specialists. There are a number of such companies offering O&M services for gas turbines.

The digital process management companies are still another set of contenders. They offer analytics and Procurement As A Service (PAAS) as part of their packages. Accenture, Wipro, and Genpact are examples.

Some of the specific players are filtration companies such as GE Water and Ovivo. Pump companies include Flowserve, and Sundyne, a division of Accudyne. Both provide other products and would have the depth to play a larger role. Danfoss is another pump supplier. Its complimentary products include drives and HVAC equipment used in pharma and chip manufacturing.

Prochem, Hach, Mettler Toledo and other instrument suppliers offer remote monitoring including input from:

- Resistivity monitors/controls

- Resistivity alarms

- Flow meters

- Pressure meters

- Silica monitors

- Total organic carbon monitors

- pH probes

- Dissolved oxygen monitors

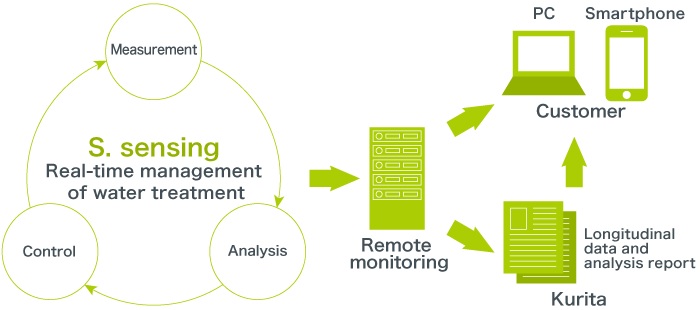

Kurita has a remote monitoring system and since it supplies water treatment chemicals it can include its chemicals supply as part of the program.

Veolia supplies complete UPW systems. The Orion package features Reverse Osmosis (RO) membranes, integral recovery RO and concentrate recycle along with purified water.

Orion includes TFT HMI with the options of Siemens and Allen Bradley PLC units. This updated HMI technology displays key sustainable parameters such as CO2, water and energy savings. The latest Integrated Smart Module (ISM) sensors have also been used for monitoring and control aspects. The Orion can be linked to the new Veolia technology, Vision. This customer portal is a private, secure web-based platform that allows access to all information regarding Orion, its products and services. Vision Air also allows for remote monitoring, giving further control and enabling access to real-time encrypted performance data, including alarms and equipment status.

Large semiconductor tool makers could also expand into UPW O&M. A leading-edge fab might contain >1,000 tools, with several dozen key sensors on each tool, and each wafer may see as many as 1,400 process steps. Huge streams of information are coming from fab tools, wafers, GDS (design) files, and facility systems such as chillers. Applied Materials is a major tool provider but also provides IIoT services.

Applied’s technology-enabled services go beyond the maintenance-driven relationships Applied has with chipmakers. Most large manufacturers are already collaborating with the company on data-driven analysis projects, drawing upon Applied’s E3 performance-tracking and data-mining software, as well as libraries and models. Applied engineers record vibration data, wafer placement images, optical emissions, and other sets of information to help enrich analysis models.

An aspect of the IIoT in pharma is the modularization of pharmaceutical production plants. IIoT infrastructure allows modular automation to scale production up or down according to market needs. This enables faster time-to-market for pharmaceutical products in accordance with the regulations and required approvals for specific markets and regions.

The challenge for the future of pharmaceutical manufacturing is to be highly flexible with adaptable automated production. Today, there are still many manual processes in drug substance and drug product preparation. Managing the data and being able to make automatic adjustments or decisions based on the data implies advances which IIoT promises to deliver. Cloud based systems can also integrate the important UPW data and make the UPW system as flexible as the rest of the manufacturing operation.

The impact of IIoT and Remote O&M will be substantial. The path to success will be complex. McIlvaine has two services to help guide the suppliers:

IIoT and Remote O&M N031 Industrial IoT and Remote O&M

UPW World Markets N029 Ultrapure Water: World Market